3.4 A-3 STAGE ENGINE

The total thrust of 48000 pounds is subdivided into three engines of 16000 -pound thrust each. This effects a shorter overall propulsion system and a shorter, lighter vehicle interstage. Furthermore, the liquid nuorine/liquid hydrogen propellant combination was chosen because of the relatively stringent performance requirements for upper stages.

Fluorine is the most reactive and energetic chemical element. It has vigorous and reliable hypergolic ignition characteristics, and superior specific impulse capabilities with most fuels. The high density of liquid fluorine, combined with high performance with liquid hydrogen, results in maximum payloads. As mission requirements become more ambitious, payload advantages from the fluorine-oxidized propellant combination should compensate for handling problems caused by fluorine toxicity and corrosiveness. Past experience has indicated that the operation of a fluorine-oxidized engine is practical at this thrust level ( 50000 pounds or less). Fluorine when used for gaseous passivation of metals renders a metallic surface resistant to future chemical reaction. Thus, once a metallic fluoride film is formed, further action by the liquid fluorine is either prevented or significantly retarded, making handling or storing of liquid fluorine less of a problem. No known elastomer is completely compatible with fluorine; however, flow tests of liquid fluorine with Teflon have given satisfactory results.

General Engine System Description

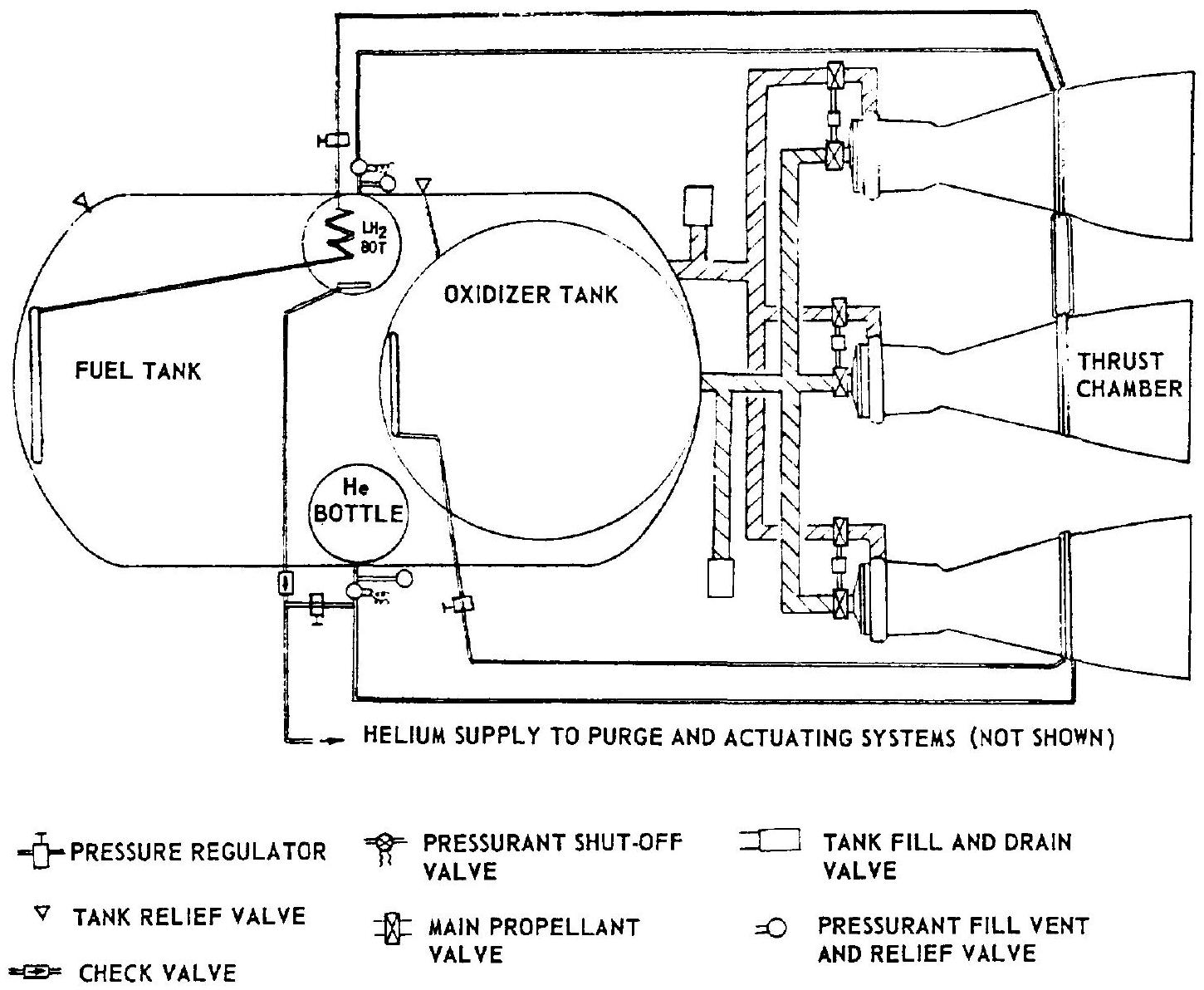

The A-3 engine is a multiple-start, gimbaled, bipropellant system. The basic system includes a thrust chamber assembly using a combination of fuel-film ( ) and radiation cooling; propellant ducts; valves; and a control subsystem. Ignition is achieved by the hypergolicity of the propellants. These are fed directly from pressurized propellant tanks, through main propellant valves, to the thrust chamber inlets. The propellant tanks and their gas pressurization system are considered part of the engine propellant feed system. Gaseous helium supplied from a high-pressure helium bottle located inside the main fuel tank is used for main oxidizer tank pressurization. The main fuel tank is pressurized by gaseous hydrogen supplied from a liquid hydrogen bottle which is pressurized by helium and which is also located inside the main fuel tank. Both pressurants are heated in heat exchangers located at the thrust chamber nozzle extensions before they are expanded through pressure regulators and transferred to the propellant tanks. Helium gas is used to operate the main valves and the gimbal actuators, and to purge the propellant manifolds during start.

A-3 engine operating parameters, for vacuum conditions, are presented in table 3-4. The propulsion system schematic diagram is shown in figure 3-6.

The design of the entire propulsion system is governed by simplicity and minimum number of components. This is essential because of the highly reactive and toxic nature of fluorine. Welded joints are used extensively. No rotating seals are employed. Sliding seals are of the metal-bellows type.

A preliminary design layout of the A-3 propulsion system and dimensions are shown in figure 3-7.

The fuel tank is pressure stabilized rather than mechanically stabilized. The thrust loads are transmitted to the payload through the fuel tank. Both tanks are insulated, as are the ducts between tanks and engine systems.

Thrust-vector control is achieved by gimbaling the thrust chambers. Each basic engine weighs approximately 330 pounds dry and 365 pounds at burnout. It has a cylindrical space envelope of 5 feet 4 inches diameter by 7 feet 6 inches length. The propulsion system (including the three engines and the tankage) weighs

Figure 3-6.-A-3 stage propulsion and engine system schematic diagram.

Figure 3-6.-A-3 stage propulsion and engine system schematic diagram.

Table 3-4.-16K A-3 Stage Engine Operating Parameters

| [Vacuum conditions] | |||||

|---|---|---|---|---|---|

| Engine (pressurized gas-feed): | Calibration orifice pressure drop | psi | 17 | ||

| Thrust | lb | 16000 | Oxidizer tank pressure | psia | 170 |

| Nominal total multiple-firing duration | sec. | 300 | Total oxidizer weight ( 300 sec duration for 3 engines, plus | ||

| 1 percent residual) | Ib | 27950 | |||

| Specific impulse | sec | 446 | Oxidizer tank volume (including | ||

| Oxidizer : | 305 | ||||

| Density | 94.16 | Pressurant (helium) flow rate | |||

| Flow rate | lb sec | 30.78 | (assuming tank gas temperature | ||

| Fuel : | ) | lb/sec | 0.1555 | ||

| Density | 4.42 | Total pressurant weight (including | |||

| Flow rate | lb/sec | 5.13 | |||

| Mixture ratio | O/F | 6 | |||

| other requirements in the system) (assume storage bottle final pressure 350 psi , plus 2 percent reserve) | |||||

| Thrust chamber (solid wall film cooled by fuel and radiation cooled on nozzle extension): | |||||

| Ib | 60 | ||||

| Pressurant storage tank, volume | |||||

| Thrust | lb | 16000 | (assume storage temper- | ||

| Specific impulse | sec | 446 | ature, including 3 percent | ||

| Injector end pressure | psia | 110 | ullage volume) | 7.35 | |

| Nozzle stagnation pressure | psia | 100 | Pressurant storage tank, initial | ||

| Oxidizer flow rate | lb/sec | 30.78 | pressure | psia | 4500 |

| Fuel flow rate | lb/sec | 5.13 | |||

| Mixture ratio | O/F | 6 | |||

| efficiency | Percent | 98 | Fuel side (pressurized by heated hydrogen): | ||

| ft/sec | 7910 | Injector pressure drop | psi | 25 | |

| efficiency | Percent | 102 | Inlet manifold pressure drop | psi | 10 |

| 1.817 | Main valve pressure drop | psi | 10 | ||

| Contraction ratio | 2 | Line pressure drop | psi | 5 | |

| Expansion ratio | 35 | Fuel tank pressure | psia | 160 | |

| Throat area | 88 | ||||

| L* | in | 28 | Total fuel weight ( 300 sec duration for 3 engines, plus 1 percent | ||

| Nozzle contour | 70 percent bell | residual) | lb | 4660 | |

| Fuel tank volume (including 3 percent ullage volume) | |||||

| Thrust vector control: | 1087 | ||||

| Minimum acceleration | 2 | Pressurant (hydrogen) flow rate (assuming tank vapor temperature | |||

| Maximum velocity | deg/sec | 15 | ) | lb/sec | 0.346 |

| Displacement | deg. | Total pressurant weight (assuming storage bottle final pressure 350 | |||

| Oxidizer side (pressurized by heated helium): | |||||

| psia, plus 4 percent reserve) | lb. | 108 | |||

| Injector pressure drop | psi | 25 | Pressurant storage tank, volume | ||

| Oxidizer dome pressure drop | psı | 5 | (liquid hydrogen including 3 | ||

| Main valve pressure drop | psi | 8 | percent ullage volume) | 25.2 | |

| Line pressure drop. | psi | 5 | Pressurant storage tank, pressure. | psia | 350 |

approximately 5130 pounds dry, 37900 pounds wet, and 5530 pounds at burnout.

System Operation

The A-3 propulsion system is designed for automatic start, on receipt of a signal from the guidance system. A similar signal effects automatic engine shutdown. One or more restarts can be made by merely sending additional start and shutdown signals to the propulsion system.

Figure 3-8 shows the operational sequence of the A-3 stage engine. In conjunction with figure , this illustrates the system starting and shutdown operations.